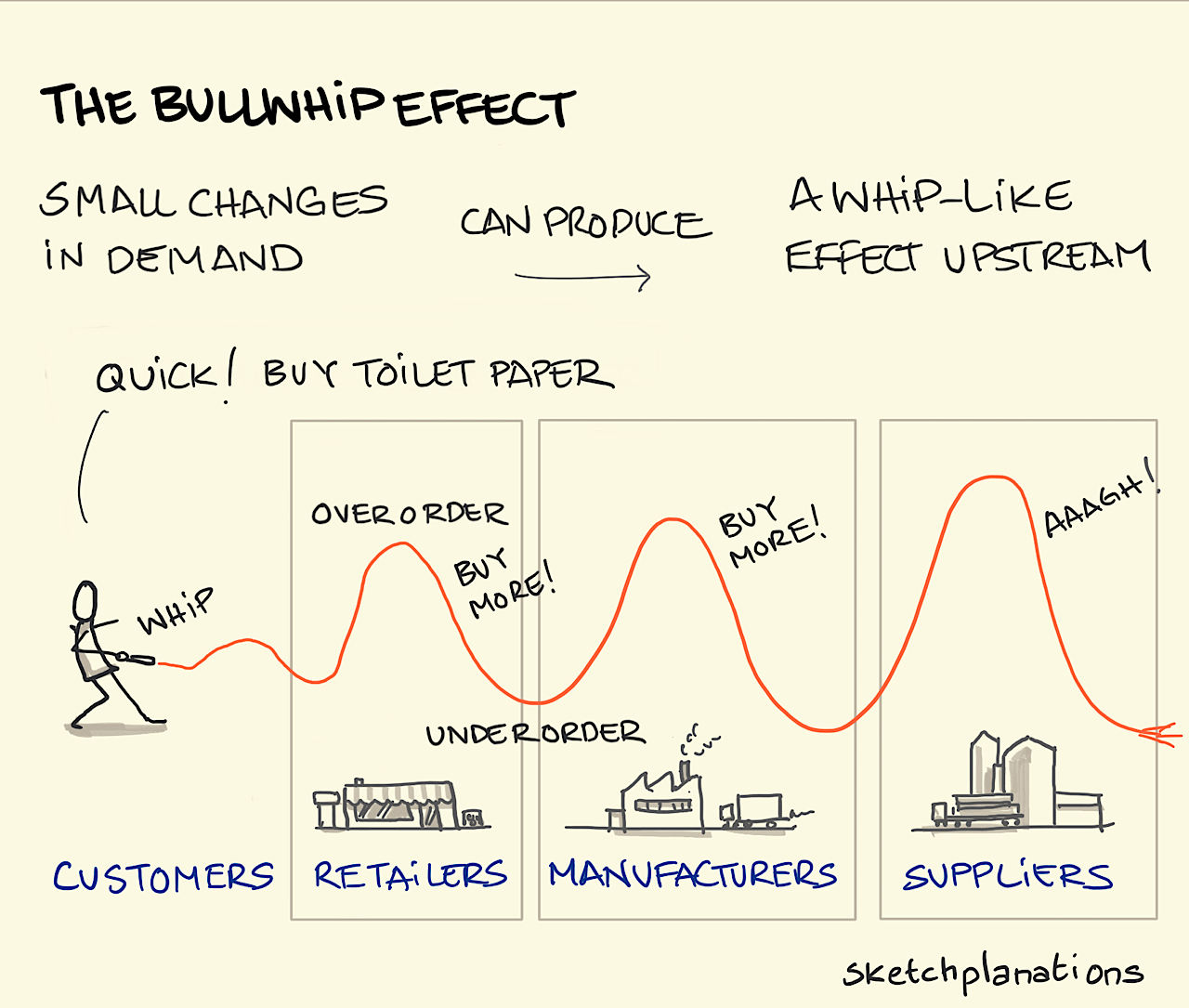

Demand swings are creating shortages. But shortages are also creating demand swings. When a product is in short supply or – worse – unavailable, we tend to overreact. We overorder to be on the safe side. This leads to more shortages and more overordering. In supply chain circles, this is referred to as the bullwhip effect – or the whiplash effect or the Forrester effect if we want to be sophisticated.

Right now, understanding the bullwhip effect is more important than ever in the history of supply chains. The swings in the bullwhip have gotten larger, causing havoc on companies – suppliers, customers, end-users alike – in the supply chain. It is not new – but the impact of the swings is much higher in the current business environment.

Understanding, forecasting, or guessing demand has always been the weak part of supply chain planning. Unfortunately, the ability to forecast has decreased dramatically during the last year. The demand swings are extremely unpredictable as consumer and business behaviors are deviating from the patterns we know. Supply chain professionals all over the world are hedging their bets, causing them to order ample supplies and preferably from many sources. No procurement professional wants to be the person whose purchases fall short, causing empty shelves or stopped production lines and ensuing discussions in the C-suite or even board room. The only safe move, seen from a job security standpoint, is to over-order.

CFO’s and shareholders alike should be concerned about the bullwhip effect. We saw and are seeing heavy write-offs following overinvestment in production capacity and in inventory following the face mask frenzy and the “toilet paper crisis”. As CFO’s learned the hard way, over-estimating demand leads to poor financial results. Under-estimating demand leads to lost sales and poor customer relationships.

Yet with unreliable supply lines and fragmented and disrupted freight lines, procurement professionals are being forced to react earlier than ever, placing orders out in the future, and locking down freight contracts.

Caught between unreliable forecasts and long unreliable supply lines, what is a supply chain professional to do? The smoother and faster the supply chain runs, the less impact from demand fluctuations. Here are some of the tools that the ALOM team applies:

Supply chain professionals are navigating through rough waters and need all the tools they can get. Great supply chain pros take into account the changing environment, the supply chain theory and the practical realities.